At Anderton Board & Packaging we offer a wide range of specialised services to meet the needs and wants of our customers.

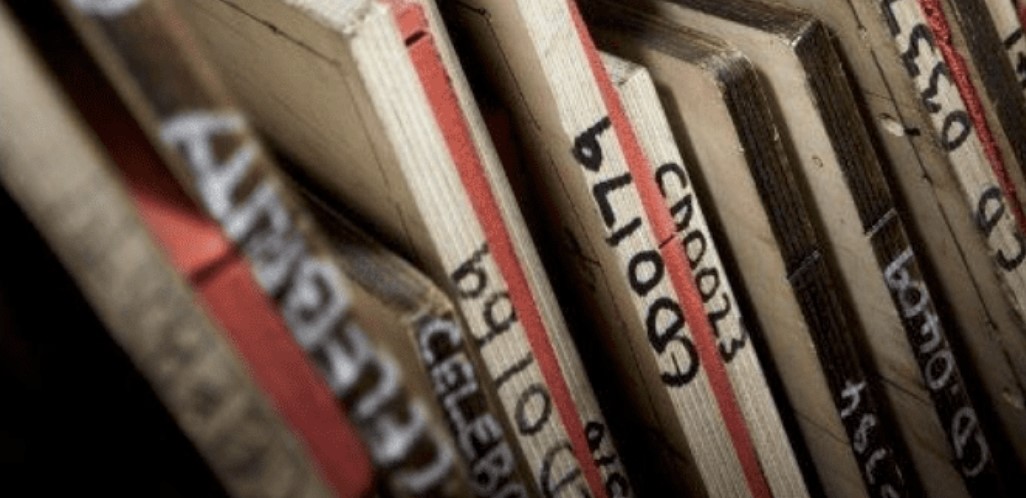

Die cutting is a process used in paperboard converting to create precise shapes and designs by cutting, scoring or creasing the material. This allows for the mass production of intricate patterns used in packaging, furniture, filter frames, bookbinding and stationery.

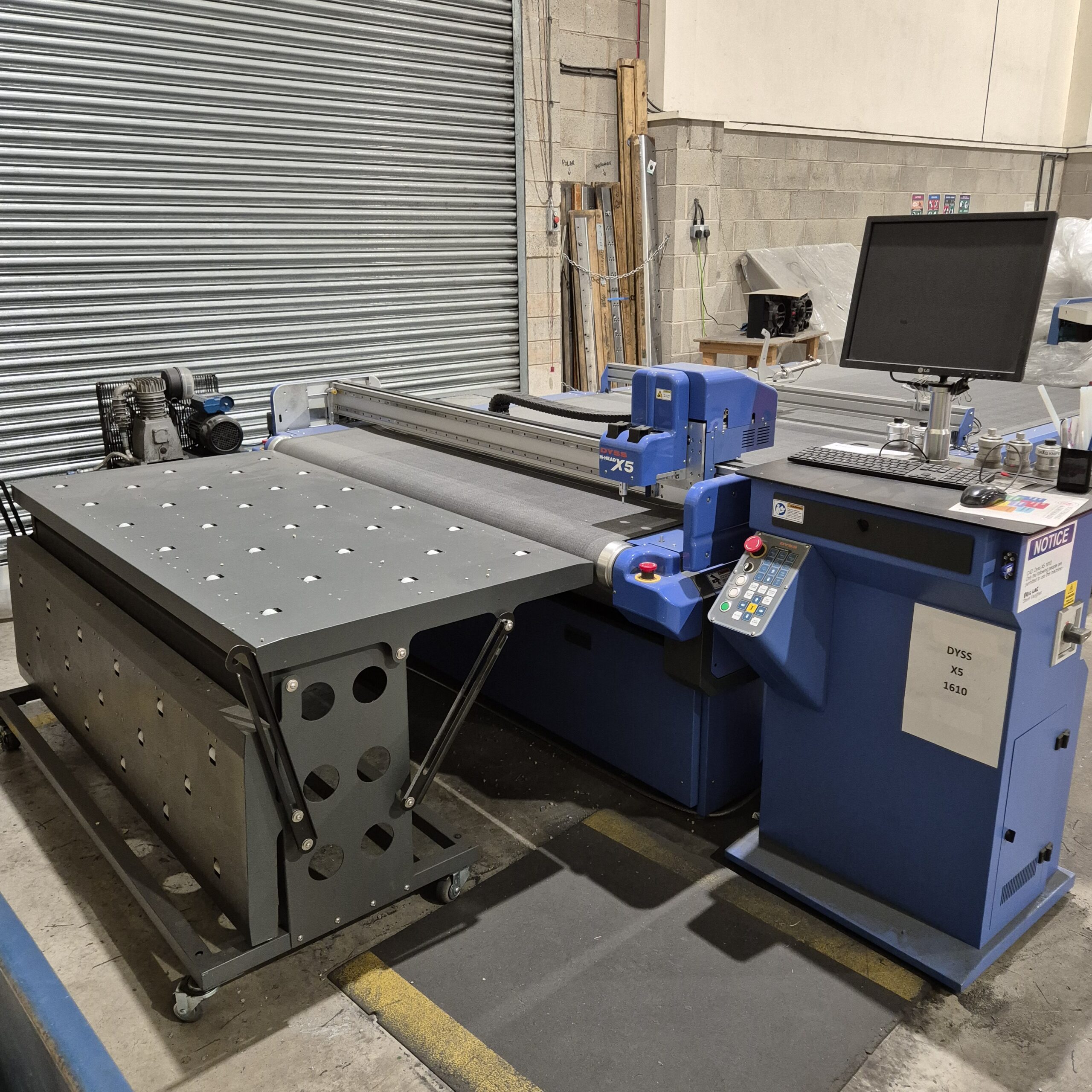

Digital Machine Cutting utilises Computer Aided Design (CAD) software to create precise cutting patterns and layouts for paperboard materials. The paperboard is then die-cut to the exact specifications outlined in the CAD programme.

Industrial guillotine cutting refers to a high capacity cutting process used in large-scale manufacturing operations. This method involves using a powerful, mechanically operated blade to cut through substantial stacks of paper or cardboard with precision and speed.

Bundling refers to the process of grouping and securing multiple sheets of paperboard together into a single unit for ease of handling, storage, or shipment. This is typically done using straps or bands to keep the bundled items organized and protected during transportation and processing.

Heat sealed bundling is a process used to group and secure multiple items together by using heat to melt and bond a plastic film or wrapping material around them. In this method, a layer of plastic film is wrapped around the paperboard or other materials, and heat is applied to seal the film tightly, creating a secure and protective bundle.

Paperboard and Packaging providers should take all three of these factors into account to ensure a quality result for their customers.

We offer a range of printing options to cover any of your printing needs or requirements:

Importantly, our solid board products also have a high level of printability to ensure that designs appear as crisp as can be!

Your Submission is Successful

We have received your confirmation and will be back in touch soon!